The De Burgh truss

Approximately 20 de Burgh type timber truss bridges were built between 1900 and 1905, with five to be retained under the Transport for NSW Timber Truss Bridge Conservation Strategy. The historical context which drove the design of the de Burgh truss was that materials other than timber had become increasingly available and economical. The de Burgh truss includes the greatest variety of materials found in any of the timber truss bridges, with de Burgh using each material to its best advantage. The result was a stiffer and stronger truss, so that de Burgh achieved the longest span (50m) timber truss bridge in NSW.

The longest span timber truss bridge was the de Burgh truss over the Lane Cove River which spanned 165’ (50 m).[17] The bridge was opened on 20 December 1900 and officially named De Burgh Bridge on 23 February 1901. A much wider concrete bridge was constructed for the increased traffic volumes in 1967 and the original timber bridge was destroyed in the bushfires of January 1994, but the 1967 concrete bridge nearby is still named de Burghs Bridge.[18]

Source: NSW Legislative Assembly: Report of the Department of Public Works for Year Ended 30 June, 1901.

Source: NSW Legislative Assembly: Report of the Department of Public Works for Year Ended 30 June, 1901. Despite Allan’s attention to detail and significant innovations, in almost every case the timber bottom chord had been the first member of the Allan truss to fail, and it was difficult to replace. The bottom chord timbers had to be of the best quality Ironbark to minimize the risk of failures, but the extensive timber export trade made this difficult to obtain and increasingly expensive.

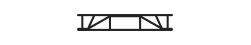

Source: Drawn by Jack Pulczynski for Amie Nicholas.

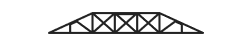

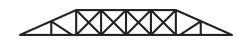

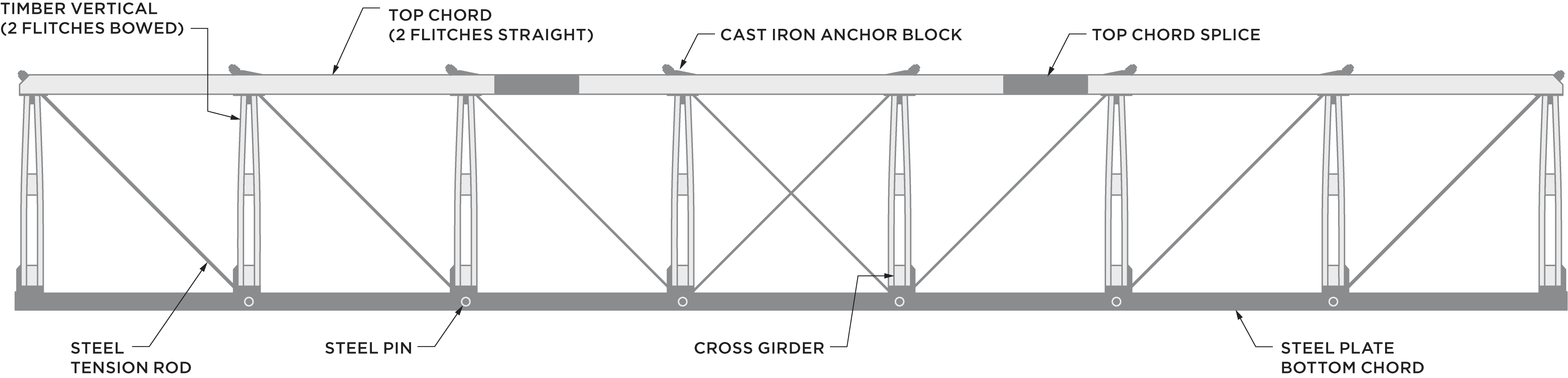

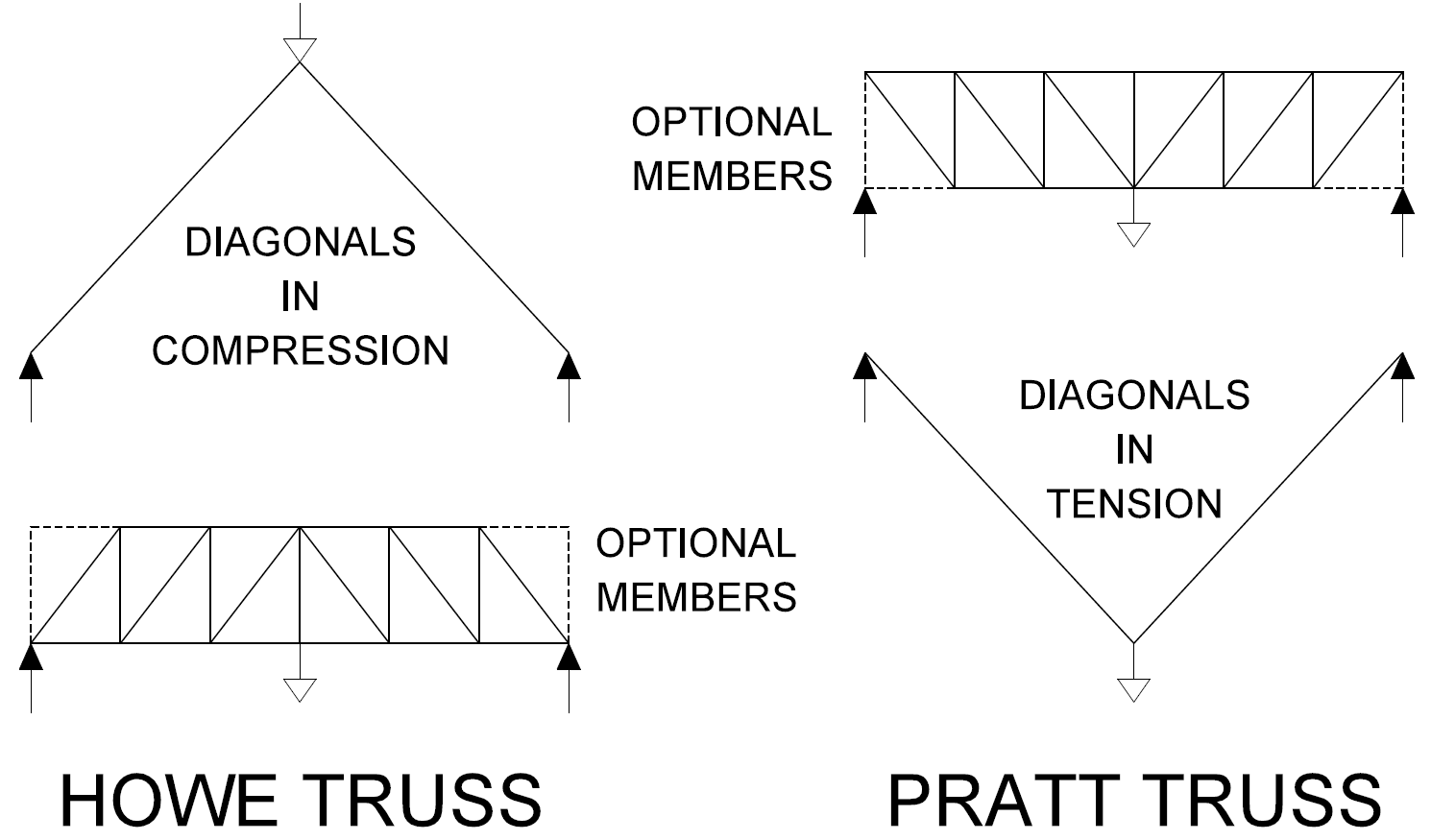

Source: Drawn by Jack Pulczynski for Amie Nicholas. The geometry of the new de Burgh Truss was based on the Pratt truss, not the Howe truss that earlier designs had used. Then chief engineer for bridge design, Percy Allan signed a number of drawings on the same day (2 April 1896) showing early forms of Pratt trusses as alternatives for bridges over the Hunter River at Morpeth and the Turon River at Wallaby Rocks, but the Allan truss was found to be cheaper to build at both places. The depth of the truss was the main structural difference between the early form of Pratt truss signed by Allan and the later de Burgh truss. The 1896 design was 10 feet (3 m) deep for the 90 feet (27.4 m) span, while the standard de Burgh Truss is 13 feet (4 m) deep for the 91 feet (27.7 m) span, a considerable improvement in efficiency. The 1896 designs also reverted to diagonal decking, had the cross girder hung beneath the bottom chord rather than above and other details that would probably have proved problematic had they been built. Within three years though, the shortage of bottom chord timbers and de Burgh’s design improvements made his de Burgh Truss more economical than the Allan Truss. Reporting on the first of the new bridges being built over the Queanbeyan River in 1899, de Burgh explained:

This bridge is rapidly nearing completion, and is of considerable interest, as, with the exception of the bridge over the Lachlan River at Cowra, it is the first in which the composite form of truss has been used in New South Wales, and also because the Pratt style of truss, with vertical posts and inclined tension members, has been adopted, in lieu of the Howe type, in order to obtain a stiff cross-section. The superiority of steel over timber in tension, and the great cost of replacing the timber chords, which, from their position, are the first portion of the truss to decay, points to a great economy in maintenance being effected by the use of this type for important bridges.

While all five types of the New South Wales timber truss bridges are composite trusses, as they all contain timber primary compression members and metal primary tension members, the de Burgh Truss and the later Dare Truss extend this principle further than the first composite truss, the American Howe Truss, as all of their primary tension members are metal.

The de Burgh Truss includes the greatest variety of materials found in any of the timber truss bridges, with mass concrete and reinforced concrete piers, rolled steel bottom chords, cast steel washer blocks, wrought iron cross girders, cast iron anchor blocks, brass in bearings and, of course timber, for top chords, verticals, stringers and decks. Using each material to its best advantage in this way demonstrates excellence in design and in understanding.

For his third bridge de Burgh made a minor but obvious technical change, replacing the sloping end members with a conventional rectangular Pratt panel, giving the de Burgh Truss its characteristic squared ends (see photos below). None of the earlier forms remain today.

Source: Left: Macintyre River at Inverell by Don Fraser; Right: Gillies Bridge over Black Creek by Amie Nicholas.

Source: Left: Macintyre River at Inverell by Don Fraser; Right: Gillies Bridge over Black Creek by Amie Nicholas. Harvey Dare was design engineer for many of the de Burgh Truss bridges including one built over the Wyong River on the New South Wales Central Coast in 1902. He explained his design intent:

The lower chords in Wyong Bridge are of the standard type adopted in this form of truss, viz., two steel plates 12 inches in depth, spaced 12 inches apart, laced together in the end bays, and connected at each apex with diaphragms and saddle-plates carrying the timber cross-girders. The vertical struts are of timber, each formed of two sawn pieces seated on the saddle-plates, and securely connected to the lower chords by extending the angle-bars of one of the diaphragms upwards, and bolting right through the verticals and cross-girder. The top chords consist of two sawn timbers free of heart, with a space of 4 inches between [sic. 8 inches]. They are connected at each apex by a casting recessed 1¼ inch into the inner side of each flitch, for the full depth, and bolted through. The notching takes the horizontal component of the stress in the diagonal-rods, and the castings, acting as rigid distance-pieces connected to the vertical struts, prevent any tendency to twist on the part of the timber flitches, and ensure that the chords shall keep a good line.

Wind-bracing, consisting of diagonal-rods with turn-buckles, is provided between the lower chords, and the top chords are stiffened against vibration by side stiffeners of T-section, connecting the chord with the cross-girders, which are extended outwards for that purpose. The diagonal-rods are of wrought iron, screwed at the upper end, and having an eye forged on the lower end, which is connected to the lower chord by a pin at each apex. The ends of the chords are seated on cast-iron bed-plates, a gun-metal or rolled-brass plate, ¼ inch in thickness, being interposed loosely between the wrought-iron bearing-plate on the underside of the chord and the bed-plate at the expansion-end of each span.

Source: Department of Public Works Annual Report, 1902.

Source: Department of Public Works Annual Report, 1902. References

[17]Don Fraser, “Timber Bridges of New South Wales”, Transactions of Multi-Disciplinary Engineering, Institution of Engineers Australia, Vol. GE9 No.2 1985, p 99.

[18]MBK, Study of Relative Heritage Significance of All Timber Truss Road Bridges in NSW, 1998, p 39.