The Dare truss

Approximately 40 Dare type timber truss bridges were built between 1905 and 1936, with six to be retained under the Transport for NSW Timber Truss Bridge Conservation Strategy. The Dare truss was designed to combine the best aspects from the de Burgh and Allan trusses while avoiding the primary problems with each. It has the simplest geometry and allows the easiest replacement of individual timbers.

By the time Henry Harvey Dare introduced the Dare truss in 1905, he has worked with Bennett, Allan, McDonald and de Burgh, and would have drawn on their extensive experience. He also had access to almost fifty years of historical data on various timber truss bridge designs used in New South Wales. His disadvantages were very limited staff (Dare later wrote that from the six years of 1904 to 1910 he worked like a galley slave, and this was largely due to considerable reductions in staff under a restructure) and the diminished timber resource.

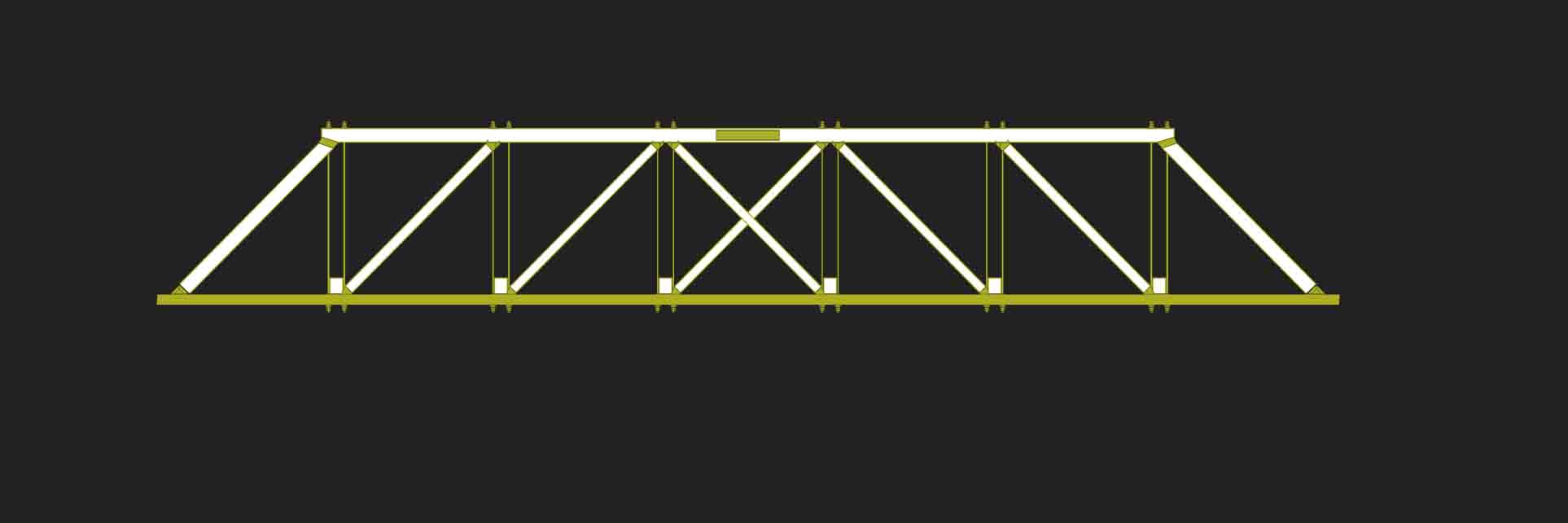

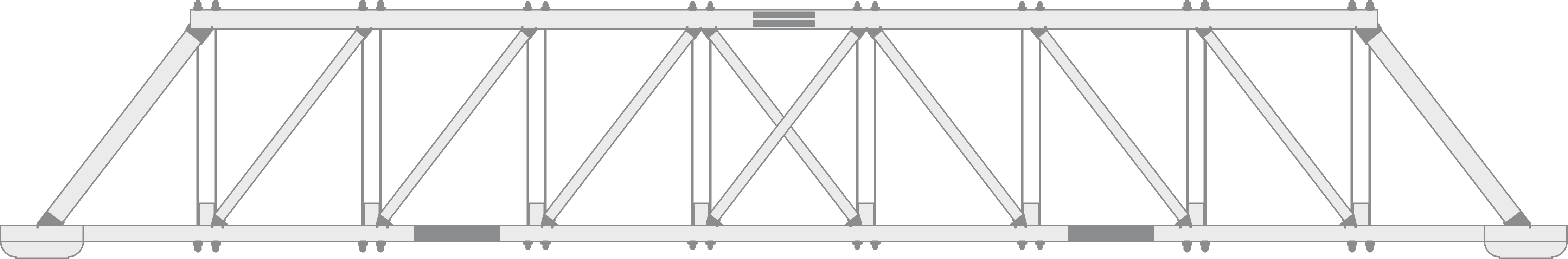

The diagram below shows that Dare did not simply return to Allan’s truss geometry, but rather, he had his own unique and very simple geometry of square panels and forty-five degree angles. Allan’s bowed top chord did not perform the structural intention Allan had hoped for, so Dare did away with the bow, thereby simplifying not only the timber fabrication, but also the fabrication of the cast iron shoes. Even though the Dare truss has a slightly longer span than the nearest equivalent Allan truss, the top chord timbers are shorter in the Dare truss, and therefore easier to obtain. The Dare truss uses less timber than the Allan truss (no timber in bottom chord, less timber in top chord and less number of timber diagonals), but this does put additional stress on the connections between the top chords and the principals and diagonals.

Source: Drawn by Jack Pulczynski for Amie Nicholas.

Source: Drawn by Jack Pulczynski for Amie Nicholas. The photos below show the straight timbers found in the diagonals and top chords of a typical 91’ Dare truss compared with the bowed timbers found in the diagonals and top chords of a typical 90’ Allan truss. The larger number of diagonals in the Allan truss can also be seen.

Source: Amie Nicholas.

Source: Amie Nicholas.  Source: Amie Nicholas.

Source: Amie Nicholas. The bottom chord of the Dare truss consists of a pair of rolled steel channel sections. The top chord splice plates are also fabricated from rolled steel channel sections. Similar to the Allan truss design, metal tension rods are located in pairs on either side of cross girders, passing through the space between the two flitches of the chords. The tension rods are designed in three sizes, with the larger tension rods located towards the ends of the spans. Similar to the de Burgh truss, metal rods are also provided under the deck between the trusses for wind bracing. Cast-iron shoes are provided at the top and bottom of all diagonal members similar to the Allan truss. T-section metal sway braces are provided on the outside of the trusses to resist sway, which are a common feature of the McDonald, Allan, de Burgh and Dare trusses.